Battery coated separator series |

|

| The self-developed bio-based polyamide coating material is combined with various adhesives and combined with ceramic or Boehmite layers. It is treated by water-based or oil-based coating process technology and adheres to the surface of base films produced by different methods. It can significantly improve the high-temperature stability of new energy batteries and enhance their safety. It is suitable for high-performance battery products, and material solutions can be customized. | |

| High security The oil-based aramid coated separator still retains elasticity and toughness after being exposed to 200℃ for 1 hour. The battery assembled with aramid separator passed through the 150℃ heat box. The pass rate of battery thermal needling is high. |

|

| Long lifespan The cycle of lithium metal batteries has been improved by 30%. The cycle of manganese-based batteries has been improved by more than 20%. The sodium-electric cycle has increased by more than 40%. |

|

| High magnification Decreased DCR; The temperature rise of high-rate charge and discharge batteries has decreased significantly. |

|

|

|

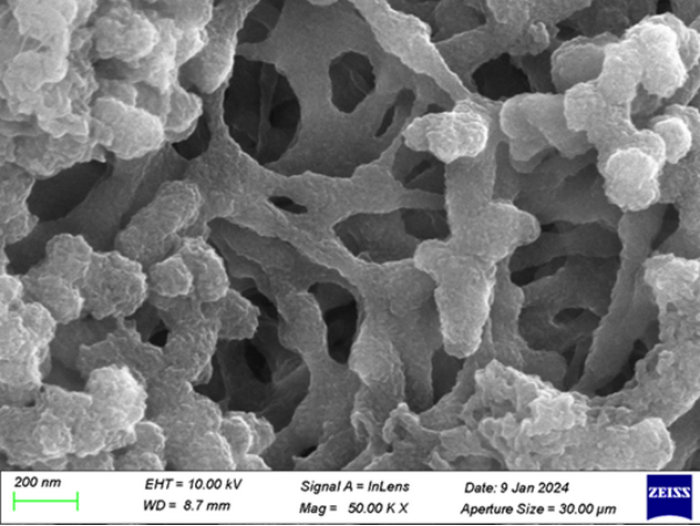

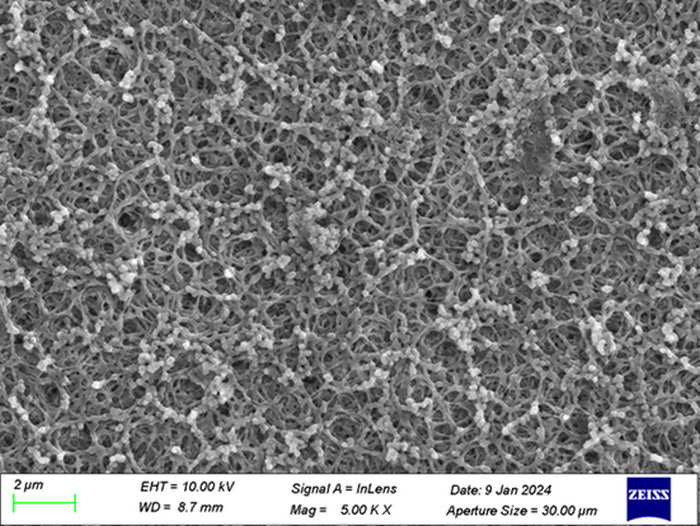

Furan-based Aramid oil-coated separator

Formula Number :BY1300

Features:

The temperature of the membrane breaking chamber is above 400℃

High cyclic structural stability

Ultra-high electrolyte fluidity

Ion capture property

Application:

Ternary power, semi-solid batteries, high-viscosity electrolytes, military batteries

| Product type | Oil coating | |||

| Product materials | Bio-aramid | |||

| Diaphragm type | 9(PE) | 2+9+2 | ||

| Product thickness | um | 8.62 | 11.67 | |

| Infiltration speed | mm/60s | 18 | 92 | |

| Surface density | g/cm² | 5.11 | 7.02 | |

| Air permeability rate | s/100m | 129 | 219 | |

| Puncture strength | gf | 463 | 535 | |

| Tensile strength | MD | Kgf/cm² | 2805 | 3013 |

| TD | 2109 | 2596 | ||

| Peel strength | Side A | N/m | / | 92 |

| Side B | / | 127 | ||

| Thermal shrinkage rate 130°C 1h | MD | % | / | 0.9 |

| TD | / | 1.00 | ||

| Thermal shrinkage rate 150℃ 1h | MD | % | / | 2.7 |

| TD | / | 3.2 | ||

| Thermal shrinkage rate 180℃ 1h | MD | % | / | 5.3 |

| TD | / | 6.5 | ||

| Thermal shrinkage rate 200℃ 1h | MD | % | / | 7.1 |

| TD | / | 7.6 | ||

| Breaking temperature | ℃ | <150 | >400 | |

- Pre:Furan-based Aramid water-coated separator ST03

- Next:none